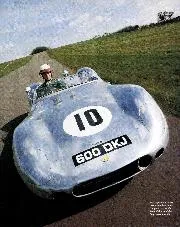

A dream fulfilled

Humble BMC underpinnings, trusty climax engine and sylphlike body were the ingredients that began a legend in 1958. David Malsher drives the prototype Anyone with a passing interest in aircraft…

by the average type of grinding machines, thus again demonstrating the benefits of the highest possible degree of accuracy in the tools with which the work is performed. In my opinion, the common practice of allowing excessive piston clearances in high speed engines is not so essential as one might suppose,provided the machine work is done on modern machine tools, where the best possible surface finish is attainable. In some cases where the compression of an engine has been increased by a considerable amount, it is advisable to make use of special vats, e caps in the case of side valve engines, and these, being provided with separate screwed plugs, can be regulated to decrease the maximum amount of compression, if necessary, by fitting plugs which are made shorter so as to reduce

the compression space. This method of adjustment is quite convenient, for in some instances it is found that the compression ratio may be too high for ordinary road work, whilst for track work and road speed trials, the benefit of the increased compression will be found vely useful.

The Manufacture of Special Valves.

As there is nothing very interesting in the manufacture of special valves, these being produced in the ordinary way on a centre lathe, except when large numbers are required, when capstan lathes are used, I do not intend to take up much space on the subject. I would, however, point out that many owners, while quite prepared to spend money in having their cylinders ground and new pistons fitted, are rather apt to overlook the advantages of fitting special valves of rather better quality than is supplied in many makes of cars.

By using such a brand of steel as the Kayser Ellison and similar types, valve wear and consequent loss of compression can be reduced to a perfectly negligible degree and, in addition to this, quite a lot can be done to improve matters by scrapping the original valves and fitting new ones of the tulip variety. In ordering new valves, it is quite a good idea to specify circlips in place of the ordinary form of cotter passing through the valve stem, as the shearing stresses on the latter are so high as to endanger failure when high engine speeds are reached. ( To be continued.)