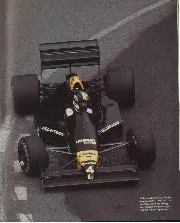

The worst car I ever drove: Julian Bailey – 1988 Tyrrell 017

It was the beginning of 1988 and I'd done a total of about six F3000 races and a handful of F3 races before that. I hadn't done a full season…

PREPARING YOUR OUTBOARD.

IL ATTENTION TO THE MOTOR.

AS the rules stand at present only standard engines are permitted for the majority of events, and therefore tuning from a racing motorist’s point of view may be only partially indulged in. The rules state that no alterations may be made except as regards controls (steering and throttle) silencer, and fuel tanks. Anyone who tinkers with compression ratios, mags. or the miniature gas works which replaces a carburettor on many motors, is to be considered quite “de trop” and is only allowed one important run of the season, namely the Bamford Trophy.

Nevertheless, there is plenty of scope for the more subtle kind of tuning, this being especially necessary when it is remembered that many other competitors in a particular race will have an exactly similar engine. It is not permissible to cram more gas in the combustion space by experiments on the depth of the ports and length of piston skirt in the case of a two-stroke, or cam contour and stronger valve springs with a four-stroke, but it is possible and permissible to induce a greater charge each cycle by reducing the skin friction between the gas and the walls of the gas passages. This, then, is first method of increasing an engine’s efficiency. There are, however, three other objects that the tuner should bear in mind : in order they are, (a) to retain all the charge when induced, (b) to afford the gases formed by the explosion, the easiest means of exit, and (c) to reduce the frictional losses of every moving part.

Personally, I favour stripping the motor down the moment it is received whether new or second-hand. When dismantling a multi-cylinder engine, care should be taken to keep the pistons to their respective cylinder, and should it also be a four-stroke, the pistons should bear an additional mark so that they may be replaced the same way round as originally. For those for whom only the best is good enough, the crankshaft should be tested for truth, for which work is necessary a lathe, a dial indicator, and the ability of a skilled mechanic. Details of work of this kind I do not think come within the scope of these notes, but it should be mentioned that there are firms such as Laystalls, who specialise in work of this kind, and anyone not confident to undertake the truing of a crankshaft should it prove out of alignment, will, I think, be amply repaid by having matters put right by a specialist firm. The next business is to start polishing ; con rods,

flyweight, inside of the crankcase and undersides of the piston should all receive attention, and as these are not bearing surfaces, emery cloth may be used for the purpose. If the mainshaft bearings are of the long plain variety, any high spots on the bearing should be removed with a bearing, scraper for not only is a perfect bearing necessary for reduced frictional losses but these bearings are the means by which the crankcase pressure is retained and any break in the film of oil in the bearing will permit air to enter and gas to escape. If the engine has never been run the main shaft bearings should be scraped in by using a fitter’s “blue.”

The “blue “is a dye which is painted over the bearing surfaces, and when the bearing is assembled and then again split, the spots which have the dye rubbed off require easing down. Should the mainshaft bearings be ball journals they may be assumed correct, but with these the pressure retaining device should receive attention. A fresh set of paper-washers should be made from cartridge-paper for all j&nts and the jointing compound should be applied thinly, care being taken that no specks of grit get between the joining surfaces, or air leaks will result. Following up the idea of retaining a good compression in both cylinder head and crankcase, a new set of rings should be lapped in, with, of course, an old or spare piston, for each respective cylinder, the medium being jeweller’s rouge. If the motor has not been run the pistons must not be touched, but they should have the high spots carefully removed with a jeweller’s file after the rnnning-in period. And now comes the most tedious work of all, that is polishing the ports. A set of riflers are useful for getting in the awkward corners but the final polish has usually to be put on by’ineans of a piece of emery on one’s finger tip unless you are fortunate in being able to get hold of a dentist’s drill which simplifies the work In this connection it must be remembered that very little metal may be removed and only a polish is permissible. Very often the vertical load on the crankshaft is taken on the bottom bevel and thus the prop-shaft bearings must be perfect, a point which is often neglected, and here it might be mentioned that it is often advisable to fill the gear housing with a thinner oil than is customary if the race is only a short one, for the loss of power through oil drag in the gear housing is always considerable.-111.