Chapman's first Lotus: Moulding the future

Colin Chapman’s first GT design shattered conventional thinking, and he took the wheel himself to prove it on track. Simon Aldridge tries Chapman’s seat for size

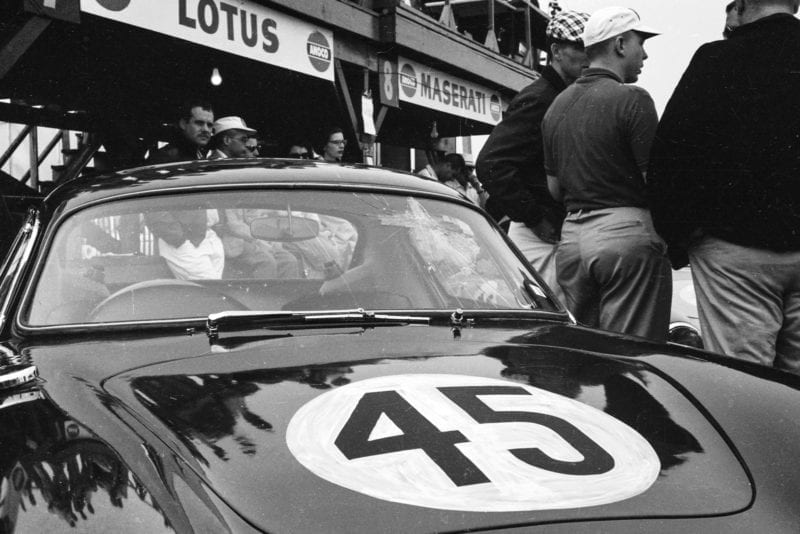

The rain came in biblical proportions. On March 21, 1959, Sebring was soaked, and it featured the US race debut for Colin Chapman’s first production car, the Type 14 Elite. Sebring rarely drains well, and Chapman’s featherweight cars skimmed uselessly over the standing water.

Sebring was the opening round of the 1959 World Sportscar Championship. American road racing had taken off during the 1950s, and the 40,000-strong crowd was anticipating a battle between the Aston Martin and Ferrari works teams for overall victory. Lotus sports racers had performed well there, with three Lotus Elevens finishing in the top 10 at the 1957 race, and that year they also had the Elite competing for production GT class honours against the Alfa Giuliettas and Austin-Healey Sprites in GT1.3, as well as the Porsche 356 Carrera GTs and AC Aces in the classes above.

Lotus brought over two pre-production prototypes of the Elite from England for the race. The car we feature, chassis number 1015-P, was for Chapman himself, and 1013-P was for Lotus’s American importer Jay Chamberlain, who was teamed with Sam Weiss. The Elite was Chapman’s first attempt to capitalise on the success of his race cars with a production road car, so a good result would help sales.

Heavy rain hit the Sebring 12 Hours in the Elite’s international racing debut

The pace of Chapman’s achievements in the lead-up to this moment is inspiring. He had built his first competition trials car as an engineering student at London University in 1947, and his first circuit racer in 1951. In 1955 he entered the Le Mans 24 Hours for the first time as entrant, constructor and driver. The next year, he drove for Vanwall at the French Grand Prix – he had helped to design that year’s Vanwall Formula 1 car – and was very nearly as fast as Hawthorn in practice, but he crashed and was unable to start. He was 28.

That autumn he conceived his Type 14 as a production car, which he could sell in quantity to fund the competition side of Lotus, just as Enzo Ferrari was doing. He took on local north Londoner Graham Hill as a mechanic and put him in charge of the prototype. A year younger than Chapman, Hill had discovered a passion for motor racing, which led him to Lotus in the hope of a drive. He was motivated and eventually completed the maiden prototype in October 1957, just in time for the Earl’s Court Motor Show, and the first running car in March 1958 for the Geneva show. The Elite was a star of both, and Hill was elevated to full-time driving in 1958 for his and Lotus’s debut in F1 – in the Type 12, fitted with the 1960cc Climax engine.

During 1958, the first several prototype Elites were completed, at the modest premises of 7 Tottenham Lane, North London. Besides development work on production and design refinements, most of these prototypes were destined to race. The competition debut came at Silverstone in May 1958, where Ian Walker took a win in the 1600cc class. Later Jim Clark and Colin Chapman battled on track in Elites at the Brands Hatch Boxing Day Meeting.

But the first international championship race for the Elites was Sebring in 1959. Chamberlain and Weiss in the pale blue no46 were the hot-shoes, but fighting through the standing water on lap 65, they suffered a blown engine and Lotus was forced to retire the car. Meanwhile, Chapman and Pete Lovely survived the rain in the dark green no45, only to have to turn their car over to Chamberlain and Weiss.

The rain had stopped in time for a resplendent sunset and gave Weiss a chance to try to catch the Alfa Romeo Giulietta Spider Veloce of Jake Kaplan and Charlie Rainville, but the heavier Alfa had fared too well during the early part of the race; the flyweight Lotus finished second in class, two laps down on the Alfa. This was good enough for fifth place overall in the GT categories, though, won by Richie Ginther in a Ferrari 250 GT California, ahead of Hushke von Hanstein in a factory Porsche 356A Carrera GT.

Passing DB-Panhard (no57) at Sebring; the Elite punched above its weight in GT class

Revs Institute

Sebring was a test of power, speed and toughness – a temporary 5.2-mile road course utilising a mix of smooth runway and poorly maintained access roads, with three long straights – and the new Elite fared exceptionally well considering that it was neither powerful nor heavily built. Chapman’s GT had beaten most of the GT class cars, including the AC Aces, Arnolt Bolide, Morgan Plus 4, MGA Twin Cam, Austin-Healey Sebring Sprite and the Fiat- Abarth 750 Record Monzas. Despite this, the American enthusiast press hailed the Elite as lovely to look at but not fast enough.

The jostling crowds in the Sebring pits didn’t agree. They were trying to get a closer look at the new Lotus because it was, from a technical standpoint, revolutionary. Chapman had conceived the car using his latest design as the basis – the Type 12 F1 car, which first appeared as a Formula 2 design in 1957. The Elite shared the Type 12’s wheelbase and suspension components, so unlike the majority of the GT competitors, the Elite had independent front and rear suspension and all-round disc brakes. The chassis was a full composite monocoque moulded from glassfibre-reinforced plastic, a world first.

Polyester resin composite technology was patented by Du Pont in the 1930s, and by the late 1940s small ‘plastic’ boats and surfboards became common. Then in 1954, Halmatic manufactured what it claimed to be the world’s first large GRP boat in the 48ft Perpetua, following early collaboration with famous racing boat designer Uffa Fox.

Elite featured world-first techniques and know-how from the boating and jetliner industries

Revs Institute

After Jaguar introduced its alloy- monocoque D-type sports car and the steel-monocoque production MkI saloon in 1955, Chapman saw the opportunity to use GRP to create a lightweight monocoque for his new production car, allowing him to build in low volumes without the tooling costs of steel body pressings or the expensive hand-formed alloy bodywork of his low-volume competitors. He was breaking completely new ground and researched the technology by listening to GRP suppliers and visiting boat and aeroplane manufacturers using the new material. Engineers at de Havilland told Chapman that modern epoxy resins and resin-bonded structures had enormous strength and were used in the wing of their Comet jetliner.

Chapman also learned that GRP had excellent strength, with the unexpected advantage that on impact the resulting damage was localised, the distortion not telegraphed through to adjacent panels. He appreciated this safety aspect of a material that dissipated the energy before it reached the driver and passenger. From conducting small-scale experiments, he concluded that GRP could handle the stress of suspension and drivetrain loads as long as the attachment points were widely spaced and isolated by rubber bushings.

“Chapman and his small team shattered precedent with the Elite”

The final body/chassis design was made up of eight enclosed torsion boxes resin- bonded together to form a rigid whole. Each front wing was a boxed section, as were the transmission tunnel, rear differential housing, roof and sills. All of the torsion boxes were made in two halves that were bonded together so that only the smooth side of the moulded resin showed. The opening panels – doors, boot lid and bonnet – were constructed in the same manner. Nowhere was the messy glassfibre side of the material visible. Hand-laid according to the expected load, panels ranged in thickness from 6mm for the undertray to 3mm for the engine bay sides. Steel reinforcement was moulded into the structure in only two locations – a tubular hoop around the windscreen, beneath the dashboard and welded to posts for the door hinges, and a steel subframe partially embedded in the chassis incorporating mounts for engine, radiator and front suspension.

Chapman and his team of a half dozen workers, working in a small North London garage, had designed a load-bearing resin structure of a type never attempted before. Chapman’s GT design shattered precedent.

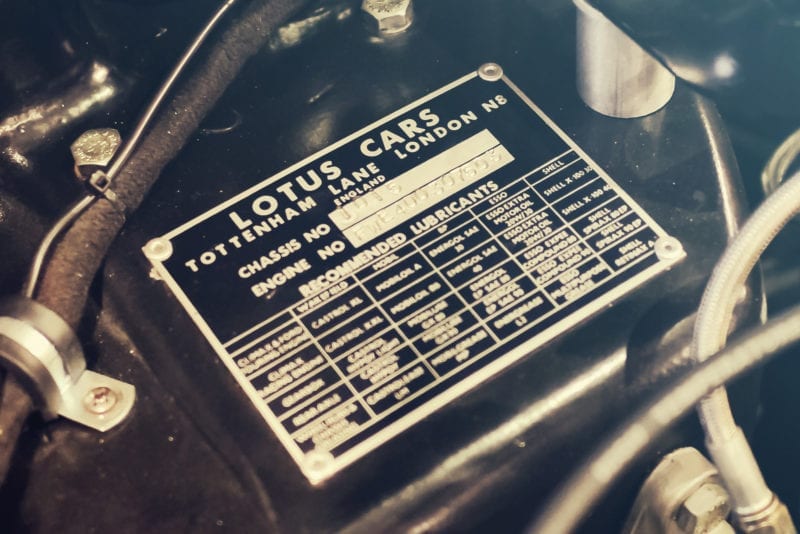

This chassis, 1015-P, was one of the prototypes built before Lotus moved to Cheshunt, in Hertfordshire, and began full- scale production. Its chassis plate proudly headlines: ‘7, Tottenham Lane, London’. After the 1959 Sebring race, the car remained in the States and was likely sold soon after. Its history file is incomplete during the 1960s and ’70s, but at some point it was repainted red. In 1990 it was listed in Dennis Ortenburger’s book Lotus Elite as owned by Kevin Kilpatrick. Later in the 1990s Kilpatrick sold it as a restoration project to Noel Chiappa, who stored the car and eventually sold it on to its present custodian, Nick Grewal. It has several features that didn’t carry over to the production cars, which Nick took care to preserve during restoration – starting with the polished fuel cap mounted on the front wing. Chapman used the front wing torsion boxes as fuel tanks by lining them with sealant, therefore saving weight, and keeping the varying weight of the fuel within the wheelbase of the car for more consistent handling.

The front and rear bumpers are handmade prototype parts in chromed brass, rather than stamped steel, and the rear shock towers have a triangular shape, which was changed for production. Nick sympathetically restored the car to race-ready condition.

The door is unlatched by a minimalist push button and finger pull, swinging open with the lightness you would expect of a Lotus.

Access is easy, despite the large sill structures, and you sit well down in the car, more D-type than XK150 – a benefit of the monocoque design. It’s race car-bare inside, the exposed GRP structures and modern roll cage finished in a light grey gloss, the only upholstery being the vinyl door cards and seats.

Chapman’s ambition to become a serious sports car manufacturer is signalled by the gorgeous 16in wood-rimmed steering wheel, which is a Lotus design with three slim alloy arms at 10, 2 and 6 o’clock. Settling into the seats, there’s lots of room in here, even for me at nearly six feet, and the major controls feel perfectly positioned. The five Smiths instruments are set into an alloy panel ahead surrounded by an elegant dashboard finished in black. It’s a comfortable and modern ergonomic proposition, except perhaps for the delicately painted steel pedals, which feel too close together. In the pictures, they look widely spaced, but that’s because they are tiny.

The engine erupts into life before quickly settling into a gruff, fast idle. When Nick restored the car he took great pains to bring it back to the Sebring specification. The 1216cc Coventry Climax FWE engine runs on twin SUs, rather than the Webers which became the preferred set-up later on. It’s a free-revving alloy four. I check with Nick, and we agree to keep it under 6500rpm today.

Coventry Climax power unit with twin SUs

Revs Institute

Nick checks the car and then sends me off to enjoy the drive over local country roads until the sunset. I was born less than a mile from where this car was built in London, so to be sitting in the same seat as Chapman himself is very special. In all likelihood Graham Hill spannered some bits on it also.

The gearbox is a BMC B-series unit with an alloy casing, and accelerating through the gears the Smiths rev counter isn’t reading past 4500rpm, so I’m changing up based on the engine note, although cacophony might be a better description – the stressed plastic shell acts like a drum, amplifying the noise and heat from the drivetrain. If you’ve driven a Lotus Seven Series 1, the Elite feels similar in steering feel. Everything else is a step-change in sophistication. The body/chassis is stiff and the independent rear suspension a revelation for its time. The disc brakes feel modern.

I’m pressing on. The broad winding road offers some long straights and well-sighted bends, and very little in the way of traffic. The gearbox is notchy with a tight gate and syncro that can’t be hurried, so acceleration is a combination of frantic revving from the engine punctuated by one-two pauses for each gear change. The gearing feels short, so I find myself in third and fourth and using the lightness of the car to keep up momentum. I’m guiding the car through bends with my fingertips, the stiff chassis and all-independent suspension gliding over the rough frost-scarred roads. Turn-in is positive, without signs of understeer; it just corners flat and grips.

Battle-worn no45 Elite was fifth at Sebring through Chapman, Lovely, Chamberlain and Weiss

Revs Institute

Compared to contemporary competition, the Elite is a revelation. It feels like a sports- racer, not a road car. Chapman’s genius in giving this car F1 suspension and a composite chassis led to an all-up weight of 505kg. Both Alfa’s Giulietta Spider Sprint Veloce and Porsche’s 356 Carrera GT 1600 racers weigh closer to 800kg. I’ve driven the Alfa in race trim; it’s a light and superbly engineered car, but the Elite feels like a purpose-built racer in comparison. Chapman must have been looking forward to racing at Sebring. The fast, flat course would highlight Frank Costin’s aerodynamic fettling. The rougher parts of the track would give the Elite’s chassis and independent suspension an advantage over the rigid-axle cars. Acceleration and braking would benefit from the low overall weight, and then there were the disc brakes, which none of the Ferraris, Porsches and Alfas had.

A class victory was not to be, but this car represents the zenith of Chapman’s ambitions for Lotus Cars. Shortly after Sebring, Lotus Engineering became Lotus Cars Ltd. But the ground-breaking Elite proved too expensive to manufacture, with rumours that Lotus lost £100 on every single one made. By 1963 Chapman realised the Elite was too advanced to be profitable and production ceased after 1076 were produced. It wasn’t until TWR/ JaguarSport and the XJR-15 in 1990 that a full resin-composite structure was attempted again for a road-legal car. Arguably, it wasn’t until the McLaren F1 of 1992 that it was seen again on a production road car. That’s how ahead of his time Chapman was with the Elite in 1957, which would win its class at Le Mans for six consecutive years, starting in 1959.

As special as the Elite is, it’s the history, and what the car represented to the young Chapman, that makes Elite no1015-P an important part of Lotus history. Designed, created and raced by Colin Chapman – a young garagista who took on motor sport greats.

Aldrige has driven the Elite’s contemporary rivals but says the Lotus is a revelation

Revs Institute

Elite featured world-first techniques and know-how from the boating and jetliner industries

Revs Institute

Grewal carefully restored race car-specific parts

Revs Institute

Simple but road car-like interior

Revs Institute

Coventry Climax power unit with twin SUs

Revs Institute

ottenham Lane identification proves the Elite’s provenance

Revs Institute

1959 Lotus Type 14 Elite

Chassis no1015-P (prototype, 1959 Sebring 12 Hours – Colin Chapman, Jay Chamberlain, Pete Lovely, Jay Weiss)

Engine: 1216cc Coventry Climax FWE four-cylinder with alloy block and single overhead camshaft, two SU carburettors

Power: 95bhp at 6500rpm estimated

Torque: 90lb ft estimated

Transmission: Four-speed BMC B-series manual with alloy casing, rear-wheel drive

Steering: Rack and pinion

Suspension: Front: double wishbones, coil-over shock absorbers. Rear: Chapman strut, trailing arms

Brakes: Girling 9½in discs all round, in-board at rear

Tyres: 4.50 x 15 Dunlop Racing L-series bias-ply tires on wire 15 x 4.5 wheels with knock-off central spinners

Weight: 1110 lbs

Performance: 0-60mph in 10sec estimated

Top speed: 112mph