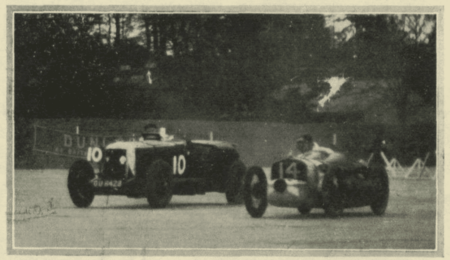

1932 BARC Brooklands Easter Meeting report

Although this was not the first event held this year at the track, one never feels that the season has really started till the B.A.R.C. have held their first meeting,…

PREPARING YOUR OUTBOARD.

SOME NOTES ON HULL TREATMENT.

With an outboard motorboat outfit, ” tuning ” the hull is every bit as important as tuning the motor, because the skin friction of the boat is the biggest absorption of power. The problem which presents itself is to obtain on the bottom of the boat the smoothest surface possible —but this is only half the story, for this surface, when obtained, must be durable against the constant washing away properties of the water, and again must be proof against the action of brine, for the boat may have to be used quite often in the sea, owing to this country’s lack of suitable inland waterways. All boats, unless otherwise specified, when received from the builders have a varnish finish, but nowadays this finish is recognised as inadequate unless it has been to a coach-builders and a real pukka coach finish put on. Those who remember Chas. Livesay’s ” Bucko ” will have knowledge of a perfect example of a coach finish, as applied to hulls, but for the majority of outboardists the fact that as good a surface can be obtained much cheaper is of paramount importance, and further, the job can be accomplished by the owner himself with little expense of time or energy. The scheme is to apply one coat of varnish, allow it to reach the tacky stage, and to dust flaked graphite over the surface. The graphite should be applied generously and the surplus rubbed off when dry. Here you have a smooth, durable surface immediately, but it is worth while to give another coat of varnish and then some more graphite. The only point to watch is to make sure that

a suitable varnish is used, such as Rylards, for many of the cheaper brands turn white and become rough under the influence of salt water.

The only disadvantage to this surface preparation is that it renders the handling of the hull a rather messy proceeding, and to avoid this many prefer to adopt one of the other methods. Perhaps the most durable is a surface prepared by rubbing down with pumice the bottom which has been painted with one of the wellknown brands of grey filling paint. It will be found that cellulose gives a very useful surface while any ordinary paint or varnish surface can be vastly improved by the addition of a little beeswax.

F.M.

Canal Racing for Motor Boats ?

At the end of last season we were at Rickmansworth for the purposes of testing an F class engine on a proposed record breaking hull. Having completed the test on the lake, someone noticed the Grand Junction Canal which flows alongside, and a run was suggested down the canal. Talking it over with the pilot he told us that doing between 45 and 50 m.p.h. down a straight half mile of the canal constituted his most thrilling trip in any motor-boat, and only the objections of a lock keeper prevented us from continuing until nightfall. From a spectator’s point of view the sight was magnificent, and the possibilities of narrow waterway races being successful seems unquestionable.