Combining this control with the [one-way clutch] mechanism made it possible to achieve both shift and gear reliability.”

The results were impressive, netting an average 0.4sec reduction in lap times, a massive gain for a single upgrade. Additionally, the reduction in torque spikes between gears, compared to a traditional sequential box, greatly improved drivability, particularly in wet conditions.

Whereas previously, if a driver shifted in a corner in the wet, the torque spike could spin the wheels, the seamless shift all but eliminated this problem.

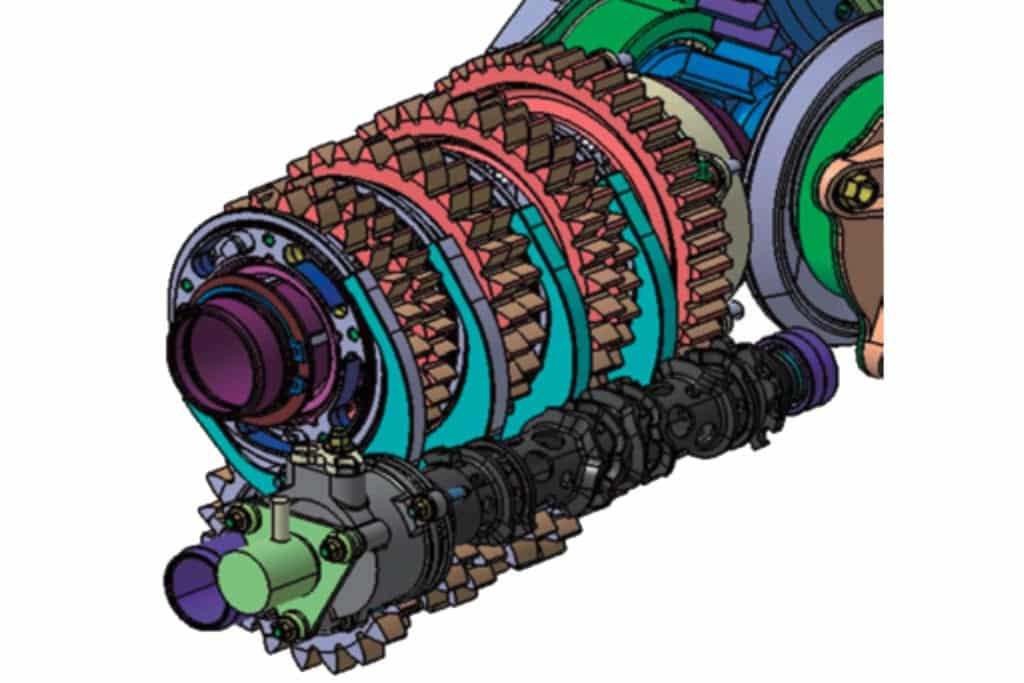

Honda was first to the grid with this revolutionary system, but others soon cottoned on and by 2008, all teams had a similar setup. However, Mano points out that while Honda used a single shift barrel other used a twin-barrel design, with even gears shifted on one and odd on another.

The benefit of Honda’s method being that it eliminated the chance of accidental selection of two gears at once, improving reliability, while also reducing weight.

Honda’s next development, due for introduction in 2009, would have seen the elimination of the traditional shift forks and dog rings from the gearbox, through the use of an internal shift mechanism. This reduced the length of the gearbox by 19% and weight by 12%; unfortunately, Honda’s withdrawal at the end of 2008 meant this never saw action in anger.