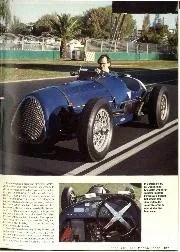

Thunder from Down Under

The Maybach began as a scrapyard special, but for a decade it was Australia's most famous home-grown racing car. Simon Taylor fulfils a boyhood dream and drives it Throughout the…

A FOUR-STROKE OUTBOARD I-47GL 1-44,

THE .17 c.c. SHARLAND WITH 0.H.V.

N outboard engine design the flat-twin two-stroke principle has predominated for many years, to the almost total exclusion of any other type. More recently, however, certain manufac

turers have been departing to some extent from the, orthodox in their efforts to gain improvement in performance arid efficiency and one of the latest and most interesting engines to be produced is the fourstroke Sharland.

This unit has been evolved not with cheapness or simplicity as the main object, but more as a serious attempt at producing a really high-grade racing engine with qualities and capabilities above the average. That such is the case is clearly indicated throughout the whole engine, and the care with which even the smallest details have been, planned, an,d the high finish of the unit as a whole are points which are at once noticeable.

The capacity of the Sharland is 347 c.c. and it has bore and stroke dimensions of 57 by 68 m.m. Each cylinder head, which is detachable, carries one inlet and one exhaust valve, which are set at 80 degrees. These are operated by tappets, push rods and rockers and a separate camshaft is used for working each valve. The rockers are carried on roller bearings and all the valve gear is enclosed by cast aluminium covers while a special lead carries a supply of oil to the inside of these covers from the crankcase ; the valves are closed by double concentric springs. The cvlindev barrels are very finely finished and adequately jacketed ; they are attached to the crankcase by four studs which are readily accessible. The crankshaft is a one piece forging made of high percentage nickel steel, hardened, ground and carefully balanced. It is carried on both plain and ball bearings of ample size. The Connecting rods are specially beat treated. The big ends run on one piece roller bearings, and the small ends carry floating gudgeon pins. The pistons are of a special aluminium alloy which has been tested to show a

tensile strength of 17 tons per square inch at 300 degrees Centigrade. Two rings are fitted to each, the lower one acting as a scraper. Ignition is by a B.T.H. magneto placed in a convenient position on an aluminium platform bolted to the crankcase. Its position in front of the engine and shrouded by the flywheel affords it excellent protection from spray. The flywheel is a steel drop forging and has a grooved plate for taking a starting cord. The oiling system is on the dry-sump principie, and a ” Pilgrim ” pump delivers oil direct to the big end bearings via oilways in the crankshaft. From there the lubricant is flung round to other internal parts. The scavenger side of the ” Pilgrim ” then draws it from the sump and delivers it to a reservoir. This reservoir or tank has

of 8/ to 1 ; with so high a ratio as this, it is, of course, necessary to use a 50-50 petrol-benzol mixture, or a suitable racing spirit. But when desired, the makers supply their unit with a lower com

pression, when it can be run on straight petrol. The fuel tank holds about two gallons and is secured above the engine by two substantial metal straps. The under-water portion of the unit is a very clean piece of work and in the gearbox and bevel housing a high degree of stream-lining has been achieved with a minimum of excrescences. The casing is made of a special aluminium alloy which is practically corrosion proof. The gear-ratio used is 13-21, and both the pro peller shaft and the driving shaft (which are of stainless steel) are supported on ball two radial and one thrust being for each. A skeg is fitted, but unit can be supplied without this, if Due attention has been given the designer to absolute watertightof the gearbox, and a well thought

out arrangement of spring loaded packing glands is fitted around the propeller shaft to provide for this. The water-circulation pump is placed on a flange on the gearbox housing above the water line. It is of

the centrifugal type and is shaft-driven at crankshaft speed. The silencer is cylindrical and water cooled, and has two heavily-finned cast aluminium end plates with fish tails attached.

The finish of the engine is of a high standard, all the aluminium parts (except the oil cooler and silencer ends). being polished ; the flywheel, tank, carburetters and all small fittings are chromium plated and’ the cylinder barrels are painted with cellulose.

It is understood that arrangements are now completed ‘for the ” Sharland ” to be put into regular production and that its. price will be about £75.