“I had no background in monocoques,” admits Gardner. “So I designed one from first principles. Ken provided me with some information, told me what other teams were doing, but there wasn’t much contact between us. I did report to him, of course, but only when there was something to report. We had resolved not to bother each other unnecessarily. I set out to satisfy myself that the design was right and, hopefully, by doing that I would satisfy him. There was no budget as such; I had a reputation for not being foolish with money, and Ken never questioned me on the topic. If there was a bill to be paid, he paid it. We kept it simple, between ourselves. Eventually, however, it became vital that Jackie came along for a seat fitting.”

And that’s why the Scot was airlifted out of a Dunlop tyre test at Goodwood. Very cloak and dagger. Gardner met him at the other end and drove him the short distance to his home.

Stewart: “I found myself outside this house in rural suburbia. It was all a bit strange. Don’t forget, at the time I could have driven for anyone; there were plenty of offers on the table. But I really wanted to stay with Ken. I desperately wanted out of March, too, but I was convinced that Ken was the right man to make that happen. I’d had no say in the choice of Derek Gardner as the designer of the new car, but if Ken thought he was the right man for the job, I was happy to go along with that. And I left that meeting firm in the belief that Derek was a good, cautious engineer. That suited me fine: I wanted a strong, safe car underneath me that I could stretch like elastic if I needed to.”

This keynote meeting lasted less than an hour because of the need to return Stewart to Goodwood before tongues started wagging.

Cockpit fairing aluminium; nose-cone fibreglass. Radiator in front

Ian Dawson

Gardner: “We asked each other lots of questions, made some adjustments, talked about this and that. Jackie, however, was surprisingly non-committal. Perhaps he was happy with what he saw. Back at the airport, I heard a bus driver ask, ‘Isn’t that Jackie Stewart?’ To which his mate replied, ‘What, here? Nah.’”

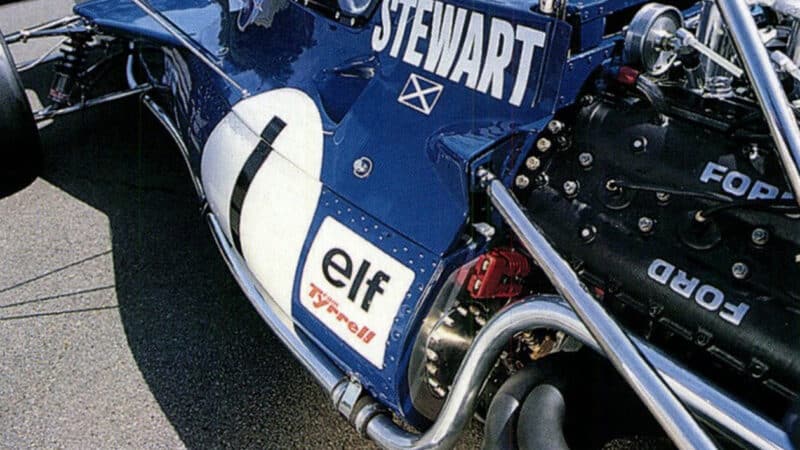

Stewart was pleased by what he’d seen. Gardner is adamant that he had not set out to design a ‘British Matra’ but a lot of what Jackie saw that day rang his bell: short wheelbase, low and centralised weight, low polar moment of inertia. He’d had enough of that “bucking bronco” March; Gardner’s mock-up was the soothing, beguiling light at the end of the tunnel.

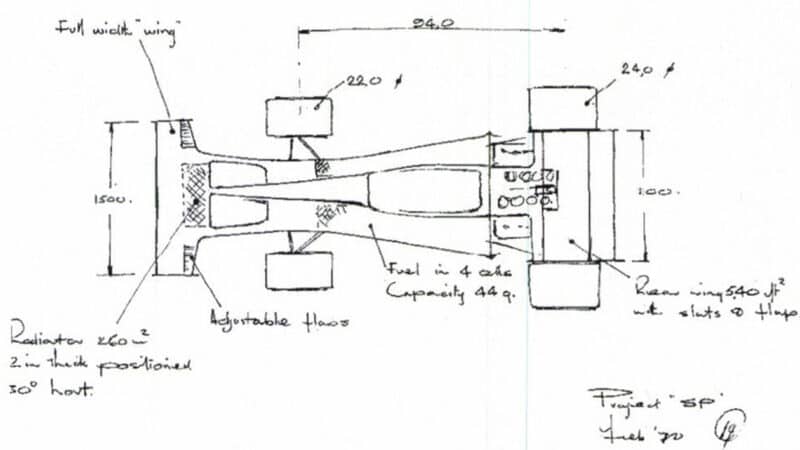

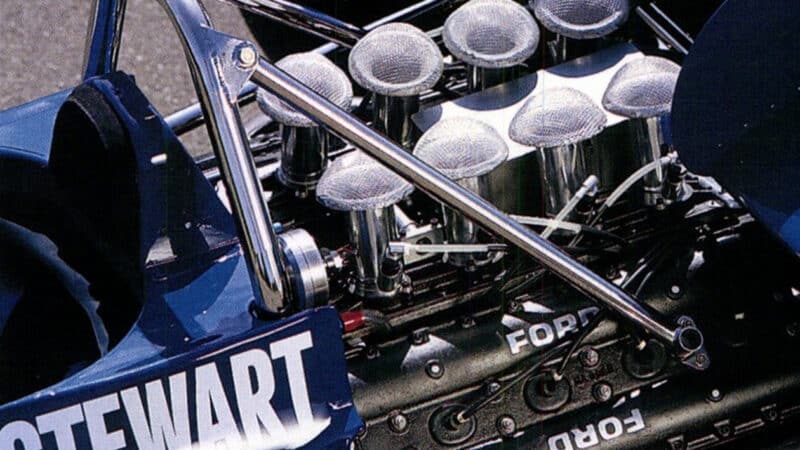

This, however, is not to consign 001 to unswerving, unthinking conservatism; in his quiet way, Gardner was pushing the envelope. No slave to convention, one of his innovations was the ‘discovery’ of carbon-like filament.