The power units are fiendishly complex and truly push the limits of engineering to levels never before imagined. “If you asked someone in 2013 about the possibility of that an engine could be that efficient, most people, myself included, would just smile at you because we would not have thought it possible,” added Marmorini.

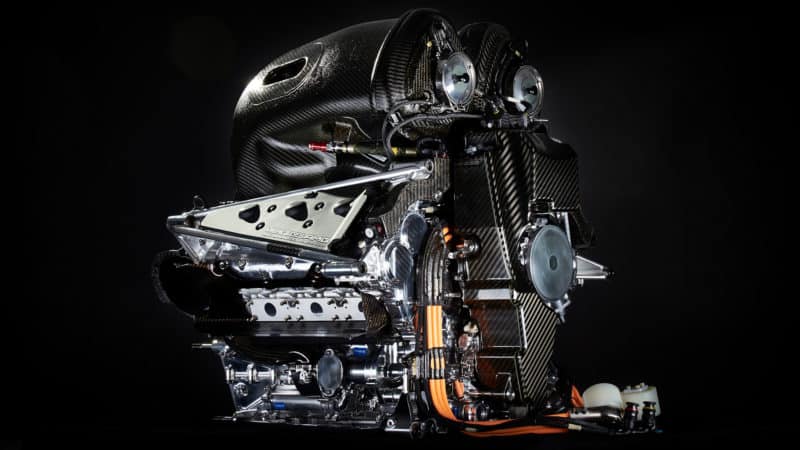

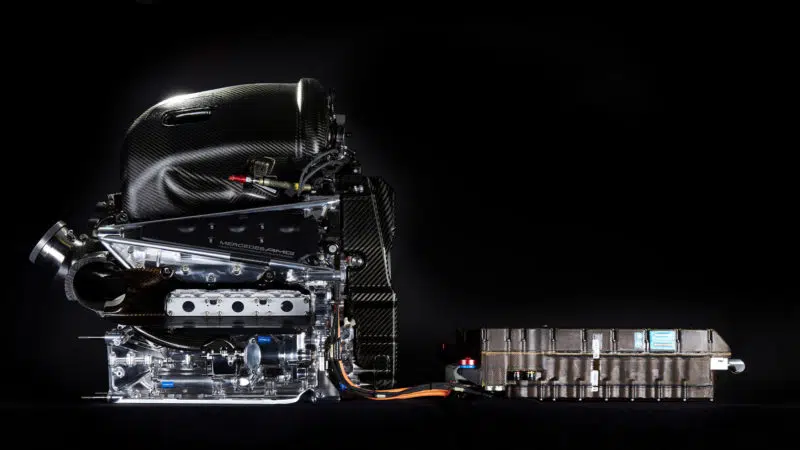

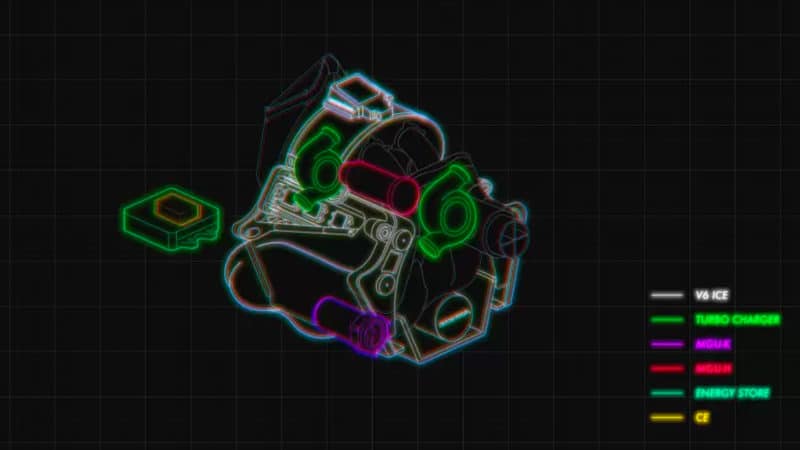

The power unit is made up of a direct injected and turbocharged 1.6-litre, V6 to which is coupled a Kinetic Energy Recovery system (the MGU-K) in the form of a motor/generator unit (MGU) with its power output capped at 120kW. This recovers energy usually lost as heat under braking, and drives the wheels when accelerating.

The second form of energy recovery comes from the MGU-H (Heat), with an output of around 90-100kW (from a motor barely bigger than a coke bottle that spins at 120,000 rpm), which is driven by the turbocharger and shares a common shaft with the turbo compressor and turbine wheels. There is then a battery (the capacity isn’t limited but per lap energy output is capped at 4MJ per lap) and the power electronics that control the motors.

Two MGUs, turbo, battery, control electronics, and V6 engine make up F1’s current power unit

Honda

The key to being fast in the hybrid era is squeezing every drop of energy from the available fuel, the flow of which is limited to 100kg/hr with an overall maximum fuel load to 110kg, while also packaging the myriad of components in the most integrated way possible, shrink wrapped under the bodywork. Mercedes was undoubtedly the team that achieved this integration most successfully from the outset and was rewarded for the time and resource it dedicated to development in the run up to 2014. In the case of Ferrari, it was not able to dedicate all of its resources to the new engine’s development until the end of 2013, with the team intent on fighting for that season’s championship.

Renault was not in a much better position and at a dinner with (former) Renault engine head Rob White and Mercedes Andy Cowell at Monza in 2014, Cowell quipped “Rob always used to joke that he had one person working on it and I had loads,” judging by White’s response, this was not far from the truth. Ferrari was also hobbled by the fact that its chassis team demanded too much from the engine department in terms of packaging, to the detriment of performance. Though its reliability was acceptable, it was well down on power compared to Merc.

So what makes the power units so complex? There are too many individual factors to list them all, but a few do stand out. The first is the efforts taken to refine the combustion process; the key to making power is efficiency with these engines and that means running exceptionally lean. The leaner the engine runs, the greater the issues with knock (where the fuel/air mix starts to combust ahead of the flame front, leading to unstable combustion and expensive noises). This means precise control is needed over combustion conditions which is where one of the more public innovations comes to light, pre-chamber ignition.