Having employed both Costin and Duckworth, Chapman was well aware of their talents and when the pair set up on their own in the late ‘50s (when Costin was in fact still Lotus technical director), a continued relationship with Lotus was logical. As the 1960s rolled around, Cosworth busied itself building engines for Formula Juniors, Formula 3 and Formula 2. This would see Duckworth start to refine his thinking around cylinder head design, later put to good use in the DFV, with the development of the SCA Formula 2 engine. That engine used the Ford Anglia 105E engine as a basis, retrofitted with an overhead cam head and gear drive on the front of the block. He focused on upping the volumetric efficiency of the engine, adopting steeply angled ports to reduce shrouding of the valves. By the mid ’60s the SCA was the engine to beat, but Cosworth had bigger plans and Duckworth was working on a design for a four-valve engine, in anticipation of new Formula 2 rules due in 1967 which upped capacity to 1600cc (from 1.0-litre).

The arrival of the 3.0-litre Formula 1 rules took the various British manufacturers somewhat by surprise. With big-banger sports cars making rather a mockery of F1’s 1.5-litre minnows, there was a desire from both organisers and teams to make the class faster. The British outfits hoped for a 2.0-litre formula, which would allow for the use of enlarged versions of the engines they already had. However, at a meeting with the FIA in 1963, which sought the opinion of teams before rules for 1966 were agreed, the British contingent – led by Chapman – opened the bidding at 3.0-litres; the FIA promptly agreed. Cue a dash to find new engines and with Coventry Climax soon to be out of the picture, there were not too many obvious options.

Ferrari and Maserati dusted off V12 designs from the 1950s, BRM decided it could take its 1.5-litre V8, stack two on top of each other having flattened the vee out and make an H16, Harry Weslake readied a V12 for Dan Gurney’s Eagles and so on. Never one for compromise, Chapman knew he needed a bespoke engine built to the formula and Cosworth would be the ones to build it. There were just two problems: time, and money.

Developing an all-new engine has never been a cheap endeavour and Chapman went off to try and raise funds, but pleas for government backing fell on deaf ears while Ford did not wish to enter Formula 1, despite its existing ties to Lotus. As a stopgap, Chapman made a deal with BRM to use its H16 while he continued the search for cash. Enter Walter Hayes, then head of public affairs at Ford of Britain, who knew Chapman well. He would bring Ford back into the game, convincing the UK operation to stump up the £100,000 needed at the end of 1965. The deal was that Cosworth would build a 3.0-litre F1 V8 and the 4-cylinder F2 motor. Duckworth and Costin had not been idle and by mid-’65 work was already underway on the latter, called the FVA, which would enter competition in 1966.

DFV design and development team, from left: Bill Brown, Keith Duckworth, Mike Costin and Ben Rood

Grand Prix Photo

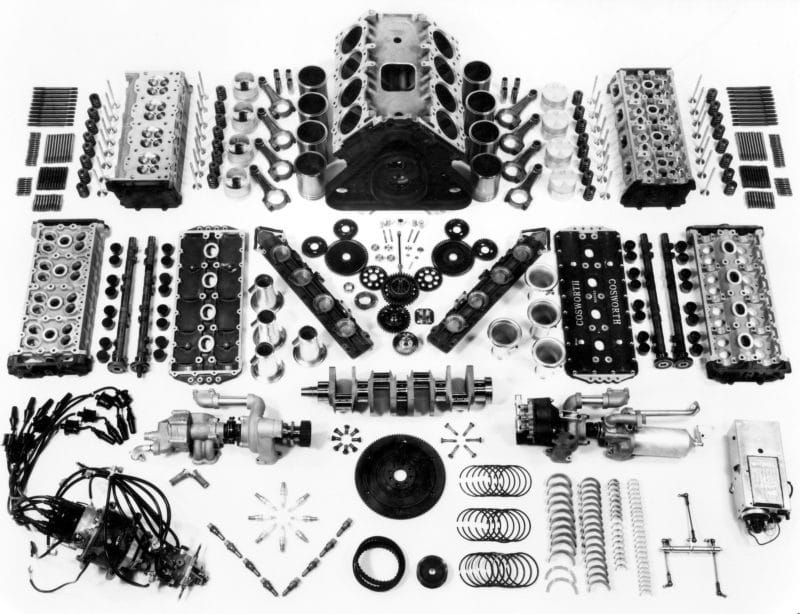

However, creating the DFV would not simply be a case of doubling up the FVA, which was still based around a production block. Duckworth had never developed an entire engine before and the DFV would require a bottom-up design; the result was not bad for a first try.

The engine would act as a stressed chassis member, so Duckworth had to account for the rear suspension loads in its structure, and the crankcase, cylinder heads and rocker covers were all designed to carry the forces through to the main monocoque. He opted for a 90-degree V-angle, keeping the engine narrow enough to not protrude beyond the monocoque sides of the car it was destined to power, the Lotus 49, and it was also impressively short. The use of a flat plane crank, which gave an even firing order, greatly simplified the exhaust layout.

Cosworth DFV: built entirely for racing, with no production constraints

Throughout 1966, Duckworth worked on the myriad of detail engineering problems, chivvied along by Costin when his machinations took too long. Freed from the constraints of a production cylinder block, such as a fixed bore spacing, he was able to take some of his earlier ideas to a new level. For example, the cylinder heads, while based on the FVA, had an included angle of 32-degrees (compared to the 4-cylinder’s 40 degrees). These worked in conjunction with a refined combustion chamber with a pent-roof rather than pure hemispherical design, Duckworth pursuing an idea of creating ‘swirl’ within mixture entering the chamber. This would better mix the air and fuel, improving combustion and thus power. The results proved Chapman’s faith in Cosworth, during initial dyno running, the engine produced 408 bhp and its low weight and compact form perfectly suited the Lotus 49, which had been designed specifically to accept it.

When the DFV was unveiled to Ford and the media, it was not quite the finished product. There were a few teething issues. The engine made its competition debut at Zandvoort in 1967, Graham Hill put the 49 on pole, but during the race, an issue – already known to Cosworth – reared its head and two teeth on the cam drive gears sheared, seizing the engine. Clark came through to take the win, but reliability issues would dog the engine through that first season. Clark took secured three wins, but only wound up third in the championship.